EMPOWERing your Business

SMA Magnetics

Dlaczego SMA MAGNETICS?

Jesteśmy wiarygodnym dostawcą innowacyjnych produktów i rozwiązań wspierającym ideę zrównoważonego rozwoju.

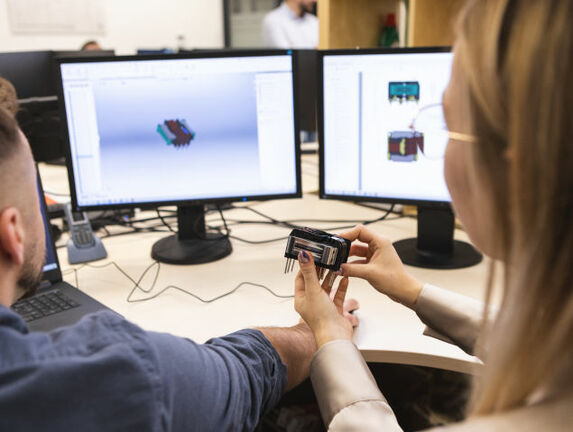

Interdyscyplinarny zespół R&D

Wysoko wykwalifikowana kadra inżynierów. Stała współpraca z uczelniami w kraju i za granicą.

Projektowanie i testowanie

Zaawansowane techniki projektowania i testowania w obszarze magnetyków, energoelektroniki i mechaniki.

15 patentów

15 Patentów w obszarze magnetyków i układów energoelektronicznych do instalacji fotowoltaicznych.

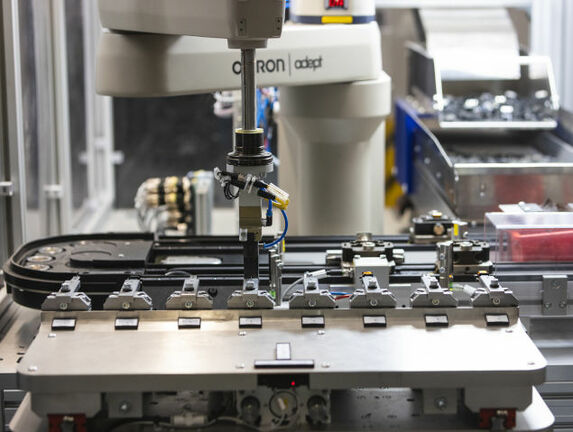

Najwyższe standardy zarządzania jakością i produkcją

Certyfikat ISO9001:2015, wdrożony System Zarządzania Środowiskiem zgodny z ISO14001:2015.

Nasze produkty

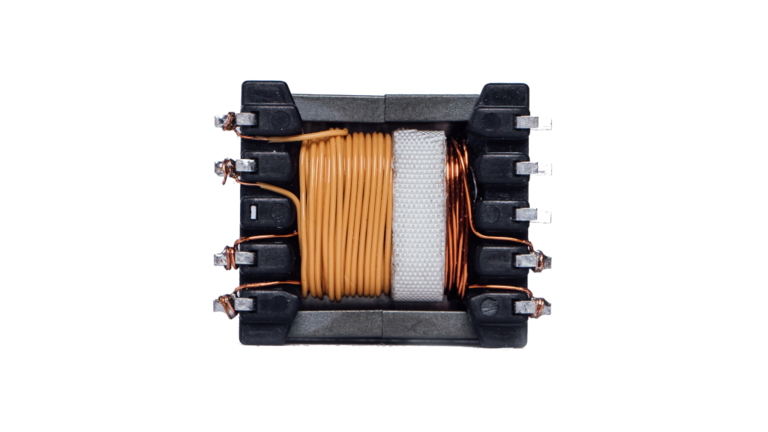

Transformatory

W ofercie SMA Magnetics znajdują się wysokiej jakości transformatory sygnałowe, wysokiej częstotliwości, bezpieczeństwa, separacyjne i transformatory mocy.

Dławiki

Specjalizujemy się w produkcji dławików dla falowników ac-dc, dla przekształtników dc-dc, dławików skompensowanych prądowo (CMC), rezonansowych oraz niskoczęstotliwościowych.

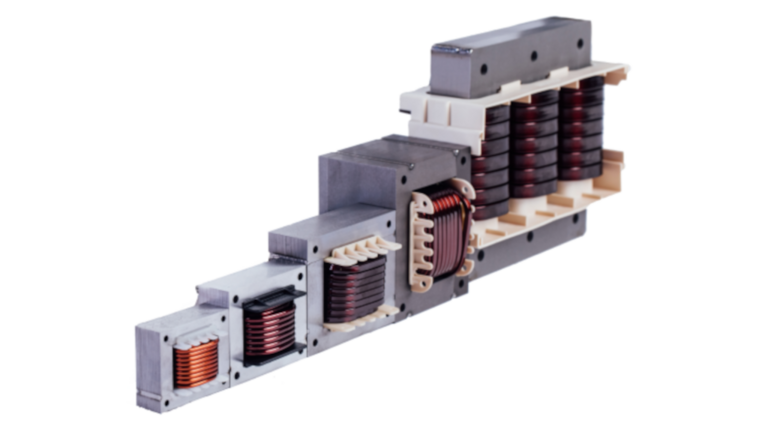

Rozwiązania specjalne

SMA Magnetics obok strandardowych transformatorów i dławików posiada w ofercie rozwiązania specjalne tj. bloki funkcjonalne elementów, filtry LCL, bloki filtrów EMI, zespoły transformatorowe.

Komponenty na PCB

SMA Magnetics oferuje możliwość zindywidualizowanego projektu elementów magnetycznych (dławiki, transformatory, przekładniki) montowanych bezpośrednio na PCB.

Segmenty rynku

Wyprzedzamy trendy rynkowe dostarczając innowacyjne produkty dla branży energii odnawialnej, kolei, przemysłu, automotive i medycznej.

Energia odnawialna

Specjalizujemy się w dławikach mocy, transformatorach oraz filtrach do przekształtników fotowoltaicznych. W swojej ofercie posiadamy również szeroki asortyment elementów montowanych na PCB do przetwarzania mocy i sygnałów.

Przemysł

Nasze produkty są niezbędne do prawidłowej pracy między innymi napędów przemysłowych, systemów sterowania i kontroli.

Kolej

Dostarczamy rozwiązania do zastosowań w przetwornicach wagonowych zapewniających zasilanie do instalacji pokładowych oraz zasilające systemy do ogrzewania rozjazdów kolejowych. Oferujemy transformatory wysokiej częstotliwości oraz filtry (dławiki do falowników oraz CMC).

Automotive

Nasze transformatory i dławiki znajdują zastosowanie w układach ładowania oraz w głównym układzie przetwarzania mocy samochodu elektrycznego. W asortymencie posiadamy też rozwiązania specjalne stosowane w układach aktywnego zawieszenia.